Overview

The School of Mechanical Engineering, established on 1 January 2026, unifies three long-standing academic and research streams at MIT Manipal: Mechanical & Industrial Engineering (1960), Mechatronics (2006), and Aeronautical & Automobile Engineering (2008). Together, they form a cohesive ecosystem distinguished by strong national and international accreditations, advanced laboratories, and extensive industry linkages. The Mechanical & Industrial Engineering stream enriches the School with a broad portfolio of minor specializations spanning design, thermal sciences, materials, manufacturing, automation, robotics, quality engineering, IIoT, coding, and Electric Vehicle Technology, the latter offered in collaboration with L&T EduTech. Complementing this, the Mechatronics stream hosts key Centres of Excellence including the Bosch Rexroth Hydraulics & Pneumatics facility, collaborative engagements with C‑DAC, and the Altair–MIT AI Research initiative. These capabilities are further strengthened through active MoUs with Orangewood Labs, Codemischief, JMAG International, and Bosch Rexroth, supporting research, training, and technology-driven collaborations. The Mechanical & Industrial Engineering and Mechatronics Engineering streams contributes interdisciplinary depth through globally aligned programs such B.Tech Dual Degree in Mechanical Engineering (2024), an international dual degree program in collaboration with Deakin University, Australia. Expanding the School’s technological breadth, the Aeronautical & Automobile Engineering stream offers a well‑structured program supported by sophisticated facilities such as a Composite Manufacturing and Testing Lab, Avionics Lab, Aerodynamics and Propulsion Lab, Structures Lab, Human–Machine Interaction Lab, and Acoustics Lab. Its research strengths span aerodynamics, CFD, AI/ML, space technology, biomimetics, composite materials, and avionics. The stream also houses the Centre for Aerospace Science and Technology (CAST) and a Centre of Excellence for Avionics, promoting advanced research and industry collaboration. A notable partnership with IN‑SPACe enables a minor specialization in Space Technology, while active student-led initiatives such as AeroMIT, DronAid, ThrustMIT, and Parikshit foster experiential learning, interdisciplinary teamwork, and real‑world problem solving. Over the years, these units have collectively developed into a centre of excellence known for rigorous technical education, innovative pedagogical practices, and a vibrant culture of research and industrial engagement. Enhancing this foundation, the School hosts specialized centres created in collaboration with prominent industry partners, including facilities supported by Forbes Marshall Private Limited and NICO – Nanobubble India Co., which enable applied research and industry-focused problem solving. It also houses the Intel Unnati AI/ML Laboratory, providing learners with state‑of‑the‑art exposure to artificial intelligence, machine learning, and data-centric technologies. ![]()

B.Tech Programs

BTech Mechanical Engineering (ME) is a four-year undergraduate engineering degree course offered by the School of Mechanical Engineering. This course provides students with the knowledge and skills necessary to design, analyze, manufacture, and maintain mechanical systems. This course offers core subjects such as theory of machines, design of machine elements, materials engineering, manufacturing processes, additive manufacturing, fluid mechanics, thermal engineering, finite element method, etc. along with a wide range of program electives to strengthen the knowledge of the students. With access to state-of-the-art laboratories and high-end softwares, students are equipped to tackle real-world engineering challenges and stay abreast of the latest technological advancements.

B.Tech - Mechatronics: Mechatronics is a multi-disciplinary domain lying at the intersection of Mechanical, Electrical, Electronics, and Computer Science Engineering. objective of the school is to enable students with the potential to address the future challenges by laying a strong foundation of multidisciplinary knowledge in their intellect. The school is well-equipped with laboratories set up in collaboration with industries to enable the students integrate knowledge from various engineering disciplines and get used to various industrial cases through. The school emphasizes on the industry academic partnership which benefits students to work in professional sphere during graduation, provides graduates with the research background necessary for an academic career, provides insights to nurture the entrepreneurship ambitions, opportunities for industrial experience, and experiential learning.

BTech program in Aeronautical Engineering deals with the design, construction, maintenance, safety and study of science behind various aircrafts and their components. For a better learning process, students are exposed to case studies and problem-based learning, brainstorming, written tests, computer simulation, group discussions, industrial training seminars, technical seminars and projects. The School offers Minor Specialization in "Aerodynamics" to Undergraduate students of B.Tech. Aeronautical Engineering.

The BTech program in Automobile Engineering deals with the study of various engines and their construction, electrical systems, alternate fuels, safety, economics and quality of an automobile. For a better learning experience, students are exposed to case studies and problem-based learning, brainstorming, written tests, computer simulation, group discussions, industrial training seminars and projects. The School offers Two Minor Specializations- "Automotive System Design" and "Electric and Hybrid Vehicles" to Undergraduate students of B.Tech. Automobile Engineering.

BTech in Industrial Engineering (IE) is a dynamic field focused on optimizing processes, improving productivity, and minimizing waste across various industries. With the rise of technologies such as AI, IoT, Industry 4.0, 3D printing, cybersecurity, quality engineering, and systems engineering, IE plays a critical role in enhancing decision-making. Industrial engineers use IoT to monitor systems, collect and analyze data, and identify inefficiencies, ultimately improving performance and reducing costs. They also leverage predictive analytics to forecast trends and recommend operational improvements. As industries adopt technological innovations and sustainable practices, industrial engineering continues to be highly relevant, with growing demand for professionals skilled in process optimization, supply chain management, and data-driven decision-making.

The School offers a dual degree program that allows students to complete two undergraduate degrees in four years. Students begin by enrolling in and successfully completing the first two years of the Bachelor of Technology (BTech) program in the Mechanical or Mechatronics stream at the Manipal Institute of Technology (MIT). Following this, they transfer to Deakin University to complete the remaining two years of the Bachelor of Engineering (Honours) program. Upon successful completion of the program, students graduate with two globally recognized degrees from two leading universities, MIT and Deakin University, enhancing their academic credentials and career prospects. (Brochure)

MTech in Computer-Aided Analysis and Design (CAAD) is a two-year postgraduate specialisation degree course offered by the School of Mechanical Engineering. This program focuses on strengthening the theoretical and practical knowledge of the students in the core areas of design and analysis to address the needs of the real world. This program aims to (a) Impart core concepts of Mechanical design to solve complex engineering problems of society and industry (b) Provide comprehensive theoretical and hands-on experience in computer-based modelling, design and analysis of mechanical components and systems and (c) Promote a culture of research and to publish research articles associated with CAAD. (Brochure)

MTech in Manufacturing Technology & Automation (MTA) is a two-year postgraduate specialization program offering comprehensive education encompassing manufacturing processes and automation. The PG program covers various subjects like advanced manufacturing processes, materials processing technologies, product design, production planning and control, computer-integrated manufacturing, intelligent manufacturing, and quality control. The program ensures all-round training in manufacturing technologies and automation, enhancing the technical expertise and proficiency to meet the demands of ever-evolving manufacturing processes and systems. The program aims to develop competent manufacturing professionals and future leaders with strong knowledge and creative problem-solving capabilities to usher innovation in the field of manufacturing and automation. (Brochure)

M. Tech in Thermal Sciences & Energy Systems offers a comprehensive blend of theoretical knowledge and practical expertise in thermal and fluid sciences. This two-year course emphasizes renewable energy systems, heat exchangers, and fluid dynamics research. Key areas include Computational Fluid Dynamics (CFD), refrigeration and cryogenics, new and renewable energy systems, and advanced thermal system design. Laboratory training focuses on stability, hybrid systems, energy, and exergy analyses, supported by high-end instruments. Multidisciplinary electives expand learning horizons, while projects and industrial training provide real-world exposure. The curriculum also incorporates research methodology and ethical practices. Graduates emerge as industry-ready experts, equipped for cutting-edge careers in sustainability, energy systems, and thermal research.(Brochure)

M.Tech - Industrial Automation and Robotics : Objective of the program is to Transform B.Tech graduates (Mechanical and Electrical streams) into Automation and Robotics Processional capable of addressing the automation challenges for effective and economic operation of manufacturing systems, development of automated systems involving robots, and develop automation strategies in compliant with industry 4.0. The curriculum is designed to train students in areas like factory automation, Digital Manufacturing, Robotics, Embedded Systems, image processing, artificial intelligence, sensorics, and machine learning with ample hands on training and enables them to learn by reasoning and research.

MTech in Automobile Engineering Course deals with the domains of advancements in engines, power trains, materials, reliability and safety of modern automobiles.

M.Tech in Avionics is a broad branch of study in aeronautical and aerospace engineering. It is still a developing and fast growing field in India and many other countries. MTech in Avionics is a two years post graduate programme in engineering, designed to explore the in-depth knowledge of avionics, aircraft instrumentations & control, navigation & guidance, UAVs, Software Safety and Security, Embedded system, Communication, Software Simulation, Sensors, Antenna Design, as their core courses and program elective. At the end of the course, the candidates will have acquired a good understanding of the major airborne avionic functions and systems and will be able to select appropriate technologies and products for a broad range of functional requirements.

MTech in Defence Technology : Directorate of Futuristic Technology Management (DFTM), Defence Research & Development Organization (DRDO), Ministry of Defence (MOD), New Delhi, Government of India (GOI), in collaboration with All India Council for Technical Education (AICTE) have started a regular Master of Technology (M.Tech) Program in Defence Technology from Academic Year 2021 - 22. The main objective of this advanced PG program is to envisage interest among young aspiring engineering graduates to pursue their professional career in research, technology and product development related to defence and security. DRDO, Indian industries and armed forces are engaged and immensely contributing in the development of defence technologies and production / maintenance of defence systems. The Government of India’s flagship initiative, ‘Atmanirbhar Bharat’ is a step in developing indigenous technology for India’s defence needs and has attracted the attention of several industries to establish many defence related industries and establishment in the recent years. This PG program aims to fulfil the increased requirement of technical expertise and trained manpower that aligns with the new demand for defence industries in India and expected to be the next big employment generation avenue in the days to come. MIT Manipal has received the approval from AICTE to start the M.Tech program in Defence Technology from Academic Year 2021 - 22 with an intake capacity of 30. This M.Tech program offers two specializations: Aerospace Technology and Communication Systems & Sensors. Semester 1 will have common curriculum to both specializations. It includes, 3 core and 2 elective courses and 2 labs. Semester 2 will be offered with courses in accordance with the specialization desired by the candidate. In addition to this, a bouquet of electives will also be provided to the students to specialize in the important domains necessary to develop advanced knowledge and skill set.

The program will be supported by the state-of-art specialized DRDO defence laboratory in India. The students opting for this M.Tech program will be undergoing their laboratory courses in some of the high-tech DRDO labs. Few courses are ably supported by the scientists from India’s prestigious defence labs, and experts from Industry who will be engaged in teaching the curriculum. Semester 3 & 4 includes the project work and seminar which can be conducted under the guidance of experts from Industry / Defence establishment.

MTech Program in Applied Computational Fluid Dynamics is designed to cater to the increasing demand for CFD specialists having practical and technical knowledge. This course is developed mutually by a consortium called APPLY consisting of 11 Universities/agencies worldwide. This course will address the needs of graduates and engineers who wish to further their career prospects in the areas of computational fluid dynamics. The program would be of interest to engineers and scientists—both aspiring and professional—with aerospace/ mechanical/ automobile/ civil/ chemical engineering applications.

The objective of Applied Computational Fluid Dynamics is to develop and understand the fundamental principles of finite element method, and finite volume methods in analyzing and solving systems involving fluid flow with wide-ranging applications from aeronautical, automobile, environmental, and heat transfer. Graduates will develop the ability to solve multi-disciplinary problems and will be a part of future development in automotive industries with proficiency in design, analysis, manufacturing, and safety features. The course is spread across 4 semesters with the first and second semesters covering fundamental topics on computational fluid dynamics and applied subjects wherein the CFD is exclusively adopted. This is supported by practical hands-on experience in simulating flows using commercial software tools such as Ansys & Matlab which are in high industrial demand. The course is equipped with courses having applications in aerodynamics, heat transfer, environmental flows, biofluids, vehicle aerodynamics, and atmospheric flows.

The School of Mechanical Engineering offers doctoral degree program in both Full Time and Part Time Modes under a wide-range research areas (but not limited to) such as Renewable and Future Energy Technologies, Non-Traditional Machining, Processing and Machining of Metals, Alloys, Composite Materials, Tribology, Computational Fluid Dynamics, Heat Treatment, Biomechanics, Thermal Sciences, Corrosion Engineering, and many more.

The School has published more than 1000 research papers in reputed International Journals and have filed for more than 50 patents in the last five years. The School is well equipped with the state of the art research laboratories and licensed software for experimental, analytical , and computational research. The admission is undertaken as per MAHE PhD Guidelines. (Brochure)

A new approach for promoting higher education for working professionals, UNNATI, Work Integrated Learning Program (WILP) was inaugurated on 27 March 2023 under the initiative of Dept. of Mechanical & Industrial Engg. enabling CIPLA employees to pursue “Diploma in Mechanical Engineering” through MAHE Manipal. It marked the culmination of a yearlong effort by both the teams from MIT Manipal and CIPLA. The diploma will be conferred upon employees upon the successful completion of six semesters, which includes a combination of onsite, online, and student directed learning.

Intel Unnati – Artificial Intelligence Data Centric Labs (Brochure)

At Manipal Institute of Technology, we are dedicated to providing our students with the latest tools and resources to excel in the dynamic field of technology. We are thrilled to announce our collaboration with Intel® Unnati to establish state-of-the-art Artificial Intelligence (AI) Labs on our campus.

Intel® Unnati is a pioneering program aimed at fostering technology inclusion and enhancing students' skills in emerging technologies. With a focus on advancing students’ capabilities in data-centric skills, the program aligns perfectly with our commitment to preparing our students for the demands of the industry. Our AI Labs, powered by Intel® Unnati, are designed to provide students with industry-leading facilities and resources. Equipped with hardware and software stack recommendations from Intel experts, these labs offer a conducive environment for hands-on learning and experimentation in the field of Artificial Intelligence.

Vision and Mission

Vision

"Excellence in Mechanical and Industrial Engineering, Aeronautical Engineering and Mechatronics Engineering Education through Research, Innovation and Teamwork."

Mission

"Educate students professionally to face societal challenges by providing a healthy learning environment grounded well in the principles of Mechanical and Industrial Engineering, Aeronautical Engineering and Mechatronics Engineering Research, Creativity, and Teamwork."

Areas of Expertise

Materials Engineering is a multidisciplinary field that develops newer materials and improves the functioning of existing materials. The discipline offers an interdisciplinary approach, focusing on synthesizing and characterizing advanced materials like polymers, ceramics, composites, nano, and smart materials. The curriculum is curated to equip the graduates with skillsets in material synthesis, development, and characterization to cater to the demands of the fast-paced world. Additionally, the theoretical knowledge is reinforced with experiential learning from working in state-of-the-art facilities dealing with computational modeling, development, and characterization of materials. The graduates can look forward to gaining employment in the energy, biotechnology, health care, aerospace, defense, and automobile sectors.

Design engineering plays a key role in successfully developing any product or system in real-life applications. The school supports the faculty, scholars, and students with well-equipped hardware and computerized laboratories to constantly engage in design-related research activities to address real world problems. The research expertise of the Design area faculty include Fluid Film Bearings, Ocular Tribology, Tribology of Polymers, Fluid-Structure Interaction, Computational Fluid Dynamics, Finite Element Methods, Vibration, Viscoelasticity, Magnetorheological Smart Devices, Experimental Modal Analysis, Passive Magnetic Bearings, Rotor Dynamics, Bearing Diagnostics, Vibration Signal Processing and Analysis, Application of Soft Computing Techniques to Engineering, Design for Manufacturing, and Fatigue & Fracture of Materials.

Thermal engineering is integral to advancements in fields like space exploration, defence, marine applications, and renewable energy. The discipline offers dynamic career opportunities at undergraduate, postgraduate, and PhD levels, fostering expertise in areas such as Solar Energy Conversion, Heat Exchanger Design, Turbomachinery, Biofuels, Microfluidics, and Computational Fluid Dynamics (CFD). State-of-the-art facilities, including simulation laboratories and thermal instrumentation setups, support both experimental and computational research. Graduates and researchers are well-positioned to drive innovation in energy efficiency, sustainability, and performance. The interdisciplinary nature of thermal engineering makes it a versatile and impactful field, ideal for aspiring engineers and innovators.

Manufacturing Engineering is vital in bridging the gap between the production and design streams. It involves working with advanced technologies where product design and manufacturing processes are integrated to produce quality products cost-effectively. Manufacturing engineering plays a key role in supporting the Government initiatives like Make in India and Aatmanirbhar Bharat. The school houses state-of-the-art facilities comprising conventional, non-conventional, and advanced manufacturing and material processing tools. The CAD/CAM laboratories aim to provide a stimulating learning experience with a focus on simulation tools, giving exposure to the creation of digital designs, manufacturing automation, and production planning and control. With the advent of Industry 4.0, in addition to developing artifacts, machine tools, tooling, and quality control, the discipline offers career opportunities in digital and smart manufacturing.

Industrial Engineering focusses on continuously improving the productivity and efficiency of all kinds of processes irrespective of the type of industry. The prominent areas of application are optimization of manufacturing processes, supply chain and logistics, decision support systems, System design, Operations management, simulation and analysis of discrete event systems and other major industrial operations. The inherent flavor of the faculty expertise in the school along with well-equipped computerized laboratory facility ensures industry readiness of students who undergo extensive training in the area of automation, data analytics, Operations research, Industry internet of things, 3D printing and design and other aspects of industry 4.0.

The school is steadily expanding its capabilities in emerging manufacturing technologies, focusing on advanced domains such as 3D Printing, MEMS, Micromachining, Nanoscience, and Digital Manufacturing, along with the rapidly evolving landscape of Industrial Internet of Things (IIoT). These areas collectively enable the exploration of next‑generation manufacturing processes—from additive and micro‑scale fabrication to nano‑enabled materials and intelligent, data‑driven production systems. By strengthening expertise in these cutting‑edge fields, the unit aims to build a future‑ready workforce and foster research that aligns with global trends in smart manufacturing, sustainable production, and Industry 4.0–enabled automation.

The school possesses strong expertise and well‑established infrastructural support in the broad field of robotics and its diverse application domains. Its academic and laboratory ecosystem is designed to provide comprehensive exposure to the design, simulation, and deployment of intelligent robotic systems. Course and lab modules span an extensive set of areas, including the design and simulation of autonomous, aerial, and flexible robots, enabling learners to work with both ground and aerial platforms. Hands‑on training in path planning and control using the Robot Operating System (ROS) equips students with industry-standard tools for building modular and scalable robotic applications. Additionally, the curriculum emphasizes robot mechanics, kinematics, dynamics, and their practical applications across multiple engineering contexts, ensuring learners develop both the theoretical depth and practical proficiency required to excel in modern robotics and automation environments.

The school offers a comprehensive postgraduate program in Industrial Automation and Robotics, designed to equip learners with in‑depth knowledge of advanced automation technologies and intelligent manufacturing systems. The curriculum spans a wide array of essential domains, including Programmable Logic Controllers (PLCs), Hydraulics and Pneumatics, and Automated Manufacturing Processing Systems, ensuring strong foundations in core industrial control mechanisms. Building on these fundamentals, the program integrates modern computational and intelligence‑driven components such as Artificial Intelligence, Machine Learning, and Image Processing, enabling students to develop solutions for smart factories, adaptive automation, and Industry 4.0 environments. By combining traditional industrial engineering principles with cutting‑edge digital technologies, the program prepares graduates to address complex automation challenges and drive innovation across manufacturing and robotics sectors.

The school also demonstrates strong expertise in foundational computing domains, encompassing Databases, Computer Networks, Cybersecurity, Cryptography, and the Industrial Internet of Things (IIoT). These areas are supported by well‑structured theoretical and practical components that enable learners to understand data management, secure communication, network architectures, and modern cyber‑physical systems. To ensure that students gain exposure to emerging technologies and industry‑relevant skills, these subjects are offered as specialized elective courses for higher‑semester undergraduate learners, allowing them to deepen their knowledge in domains crucial to intelligent manufacturing, secure automation, and Industry 4.0–driven engineering workflows.

The School has the expertise and infrastructure for subsonic flows across automotive, aircraft and building aerodynamics.

The Advanced Composite Materials lab contains state-of-the art infrastructure for fabrication of composite materials and mechanical characterization- Tensile, Compression, Flexural bending, Impact, Torsion, Hardness, and Fatigue. The facilities like Non-destructive testing, and ultrasonic C-scan for failure assessment.

The School has given keen attention to this vital branch of science for propelling the aircrafts. The lab promotes exposure to Nozzle flows, Free Jet and Wall Jet measurements, burning velocity in premixed combustion, efficiency of turbomachines used in propulsion, and mini-gas turbine experiments.

Emphasis is given to the experimental methods for the analysis of structural loads on aircbraft structural components, the modes of failure and corrective action to prevent such failures.

The school is specialized in the wear and frictional studies of bearings, friction linings for automobiles, Slurry erosion test setup for wear analysis under marine conditions.

The school has procured advanced powertrains for IC engine driven, Test Rigs for electric and hybrid electric vehicles, Regenerative braking.

The school is gaining prominence in this niche area of research spanning biomechanics, biofluidics and biomimetics.

Active research is being conducted on dynamic properties of smart material based dampers (Magnetorheological elastomers and fluids), Acoustic characterization of different materials.

External Collaborations

Specialized Labs

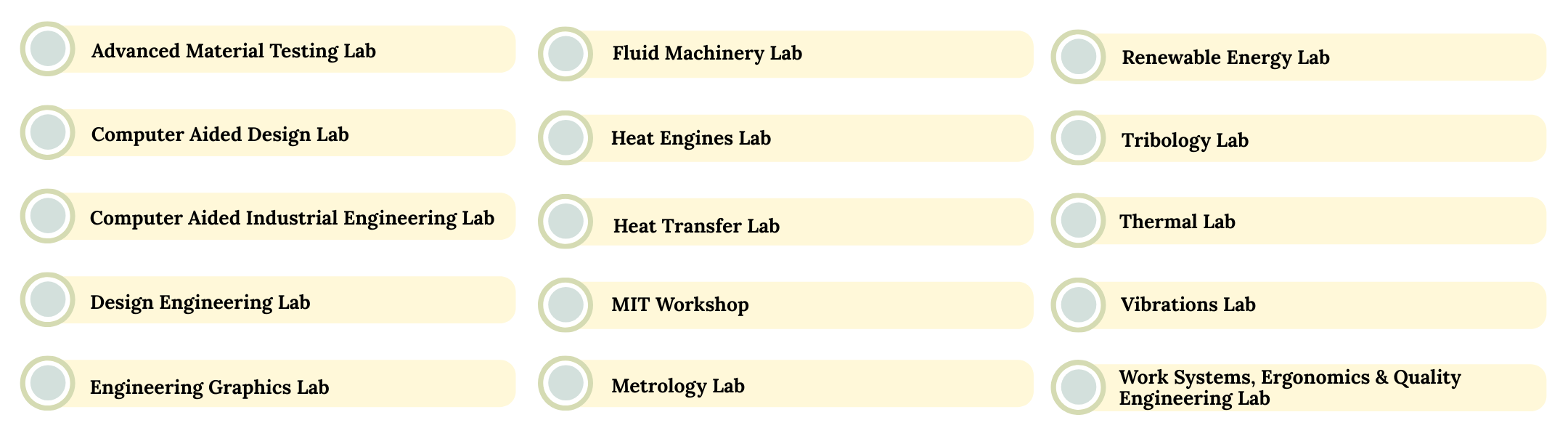

The school provides dedicated lab facilities for running lab-associated courses to undergraduate/postgraduate/research programs in the following areas of Materials, Design, Thermal, Manufacturing & Industrial Engineering. (Know More)

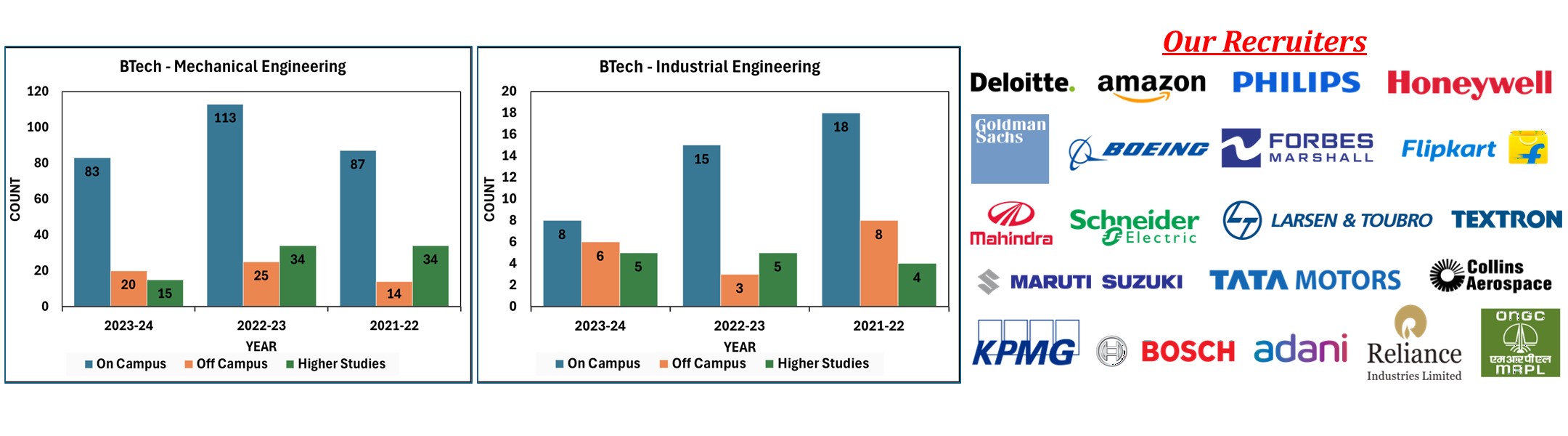

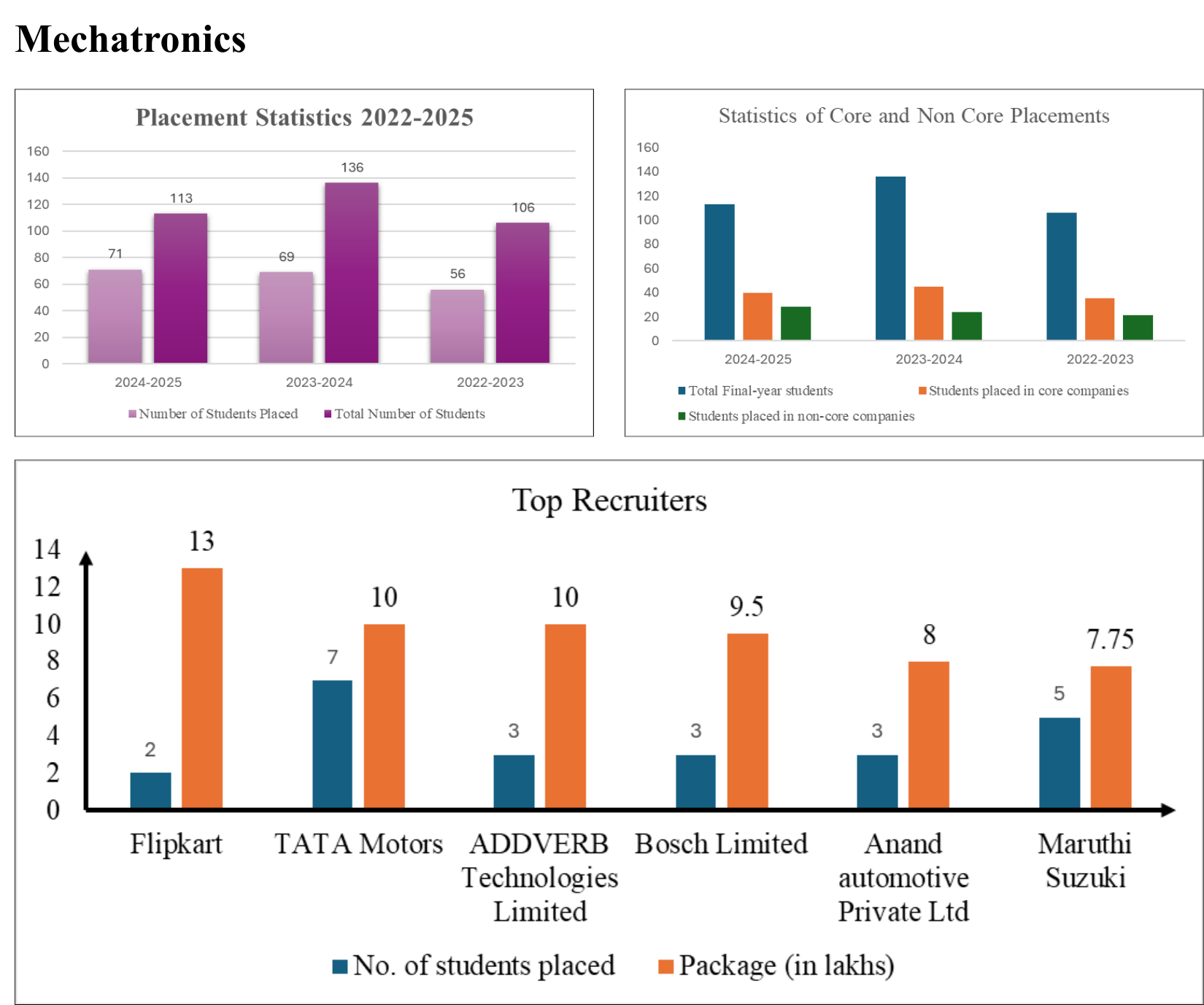

Placement Details

The school is well supported by the Institute placement team. The placement team is headed by Associate Director (Industrial Liaison, Placement & Practice School) and oversees the entire placement process in the institution with the help of school coordinators. Students are provided with opportunities for Internships, Placements, Pre-placement offers (PPO) in core companies and ITES. Our students from School of Mechanical Engineering get recruited by a wide range of companies. (Know more)

Faculty

News and Events

- Conducted BIS Lectures and Panel Discussion on 30 January 2025 to foster awareness about standardization and its applications.

- Mr. Amit Kapur of Nanobubbles conducted Academic Engagement and Collaboration Discussions - Nanobubbles (16-10-2024)

- Dr. Sadanand S Kulkarni of Propulsion Division, CSIR conducted Academic Engagement and Collaboration Discussions - CSIR (28-09-2024)

- Anant Karegaonkar and team of Forbes Marshall conducted Academic Engagement and Collaboration Discussions on 11-09-2024

- Prof. Ir. Dr. Mohd Zulkifly bin Abdullah of USM Malaysia conducted Guest Lecture Series on Electronic Cooling and Computational Fluid Dynamics (16-09-2024)

- Mrs. Mythili Belle Kamath, COE in Aerospace at Honeywell conducted webinar on Career Opportunities at Honeywell (24-08-2024)

- Prof. Sateesha Krishnamoorthy of University of Surrey conducted faculty interaction for possible academic and research engagments (16-08-2024)

- 2024 IEEE International Conference on Augmented Reality, Intelligent Systems, and Industrial Automation (ARIIA-2024), Hybrid Mode on December 20-21, 2024. (Know more)

- International Conference on Maintenance and Intelligent Asset Management (ICMIAM 2024),16 - 17 December, 2024 | Venue - Manipal Institute of Technology, Manipal, Karnataka, India (Know more)

- Keynote Lecture in International Conference ICMIAM 2024: Scenario Planning for long life infrastructure- balancing risk, climate and performance with cost - Ashay Prabhu, Co-Founder, Modelve. (Know more)

- Four days workshop on "Advanced Research Designs and Ethical AI in Research," delivered by Dr. Ritesh Bhat, Professor, Department of Mechatronics Engineering, Rajalakshmi Engineering College, Chennai, June 3rd to 6th, 2024. (Know more)

- Invited talk by Dr. Rashid Zafar, Assistant Professor, Department of Mechanical Engineering, ZHCET, AMU, Aligarh on Finite Element Modeling of Liquid Reinforced Soft Composites, 18 April 2024, 11.30 AM - 1 PM. (Know more)

- Alumni Talk by Mr Vijay Singh, CEO, IcSoft, India - Digitalization in Manufacturing (Industry 4.0), 10 April 2024, 5-6 PM. (Know more)

- Visit of Mr. Harish Shah (alumnus of MIT, Mechanical Branch,1975-80 batch) along with his wife Mrs. Bina Shah, 6-7 April 2024, MIT Manipal. Mr. Harish Shah is Founder & Managing Director, Signet Capital Pvt. Ltd and also Director, Harish & Bina Shah Foundation. Mrs. Bina Shah is Co-Founder, Signet Capital Pvt. Ltd.

- Five days hands-on workshop on Instrumentation and Data Analysis in Solar and Thermal Engineering Research, April 08 - 13, 2024 (Brochure)

- Alumni Talk by Dr. Apurva Anand, Professor and Director, Maharana Pratap Engineering College, Kanpur - Artificial Intelligence in Mechanical Engineering, 03 April, 2024, 5-6 PM. (Know more)

The school of mechanical engineering publishes Bi-annual E-Newsletter “News Links”, highlighting the school's events/news, faculty and student’s achievements, recognition and awards, student club activities, and Alumni interactions.

Click the following links to view the E-Newsletter

Research

The areas of research are

• Tribology • Computational Fluid Dynamics • Characterisation of Metals, Alloys and Composite materials • Machining of Metals, Alloys and Composite materials • Heat Treatment of Metals • Thermal Sciences • Renewable Energy Harvesting • Corrosion Engineering • Biomechanics • Non-Traditional Machining • Industrial Engineering • Supply Chain • Microfluidics • Electro kinetics

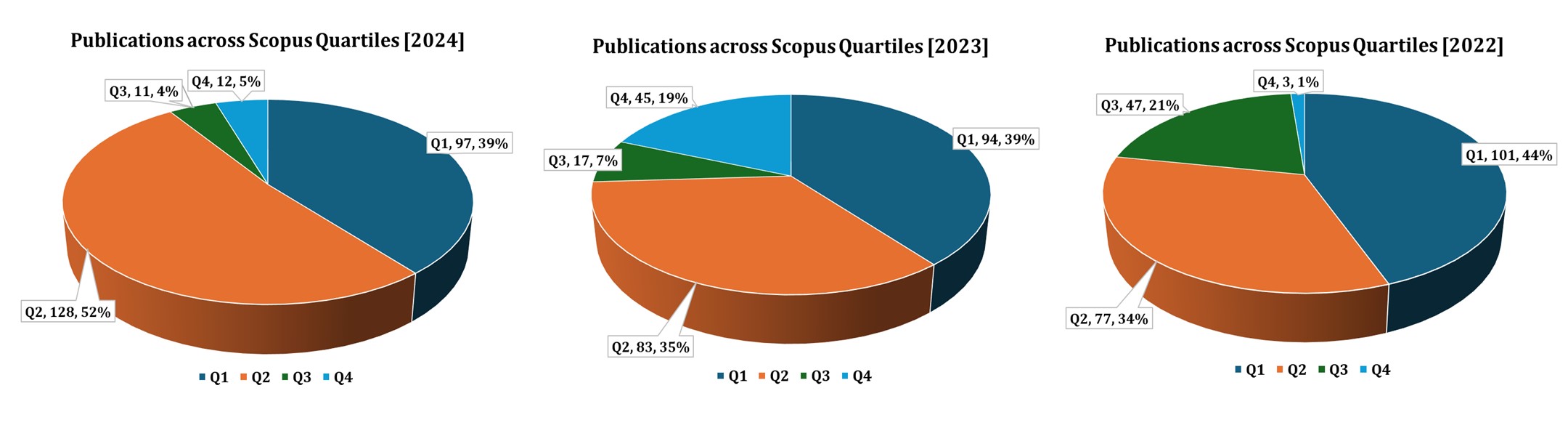

Research Publications (2024): (Know More)

Patents Granted: (Know More)

Grants/Consultancy Projects: (Know More)

Central Facilities

Laboratories

World-class laboratories give learning a practical dimension

Innovation Centre

State-of-the-art Innovation Centre to facilitate multi-disciplinary research

Libraries

Libraries have excellent resources for reference and study

MUTBI

Manipal Universal Technology Business Incubator (MUTBI)

Computing Facility

Wi-fi campus with modern computing and digital facilities

Distinguished Alumni

Director at Ace Designers Ltd. (Ace Micromatic Group) Batch of 1982-86 (I &P Engg.)

Mr. Harish Badanidyoor

Chief Executive Officer AFE - Tractors and Farm Equipment Limited Batch of 1992-96 (I&P Engg.)

Mr. Sandeep Sinha

Vice President (Marketing and Contracts) Power Transmission Business, Triveni Engineering & Industries Ltd Batch of 1983-87 (Mech. Engg.)

Mr. D Srinivasan

Chairman at Maini Group Batch of 1985-89 (I&P Engg.)

Mr. Sandeep Maini

Founder and Managing Director of Signet Excipients Pvt Ltd. Batch of 1975-80 (Mech. Engg.)

Mr. Harish Shah

Senior Advisor, Tata Sons Pvt Limited Batch of 1980 (Mech. Engg.)

Mr. Banmali Agrawala

Principal Engineer, CT Hardware Platform, GE HealthCare Batch of 2003 (M.Tech CAAD)

Mr. Vishwanath Nayak

Senior Engineer, Trane Technologies, Clarksville, Tennessee, USA Batch of 2013 (M.Tech TSES)

Mr. Princeton Lobo

Technical Innovator, John Crane, Dubai Batch of 2009 (M.Tech Mfg. Tech and Automation)

Mr. Pruthvik Kekuda

Scientist-C & Deputy Director, Bureau Of Indian Standards, New Delhi Batch of 2014 (Mech Engg.)

Mr. Prasoon Yadav

Team Lead- COSMIC Industrial Laboratories Ltd (PhD Study period: 2021-2024)

Dr Srinivas Doddapaneni

Assistant Technical Officer - Ontario Power Generation, Canada (PhD Study period: 2018-2021)

Dr Elton Dylan Nazareth

Executive Director & CEO at Godrej Industries Ltd. (Chemicals), Batch of 1988-92 (Mech. Engg.)

Mr Vishal Sharma

Student Achievements

BTech Mech Engg (2024 Batch) Part of Research Team in University of Michigan to lead first satellite mission with NASA grant worth $10 million.

Shivani S

BTech Mech Engg (2019 Batch) Achievements: Invention patent - "Universal Self Aligning Automated Gear Hobbing Fixture" granted in November 2023

Mr. Udit Rathee

BTech Mech Engg (2017 Batch) Achievements: Invention patent - "Pantograph Suspension System and Method for Vehicles" granted in March 2024

Mr. Akshay Saxena

BTech Mech Engg (2019 Batch) Achievements: Invention patent - "Device for Inspecting Dimensions of a Tool Holder" granted in March 2024

Mr. Dhruv Shah

3rd year Mech Engg student Completed SURGE fellowship at IIT Kanpur in June 2024.

Mr. Gujjadi Sathvik

Best Paper Award in ICMIAM 2024 International Conference BTech Mechanical 6th Semester

Srinidhi Deshmukh

Won 1st place in national level technical competition, "MechAura-2024" hosted by Pratt & Whitney India. (BTech Mechanical 8th Semester)

Megha Nair

Won 1st place in national level technical competition, "MechAura-2024" hosted by Pratt & Whitney India. (BTech Mechanical 8th Semester)

Pradamya Mahajan

Secured 1st Place and won a Cash Prize of Rs 50,000 in the Outstanding Project Awards 2024 by Forbes Marshall Pune (BTech Mechanical – 2024 Batch)

Mr. M Sarath Chandra Reddy

Secured 1st Place and won a Cash Prize of Rs 50,000 in the Outstanding Project Awards 2024 by Forbes Marshall Pune (BTech Mechanical – 2024 Batch)

Mr. Lalith Surya Mamidipalli

Secured 1st Place and won a Cash Prize of Rs 50,000 in the Outstanding Project Awards 2024 by Forbes Marshall Pune (BTech Mechanical – 2024 Batch)

Mr. Advay Srinivas Nikam

Secured Runner-Up Position and won a Cash Prize of Rs 25000 in the Outstanding Project Awards 2024 by Forbes Marshall Pune (BTech Mechanical – 2024 Batch)

Mr. Akhil Jayesh Mhatre

Secured Runner-Up Position and won a Cash Prize of Rs 25000 in the Outstanding Project Awards 2024 by Forbes Marshall Pune (BTech Mechanical – 2024 Batch)

Mr. Kare Yugeshwar

Secured Runner-Up Position and won a Cash Prize of Rs 25000 in the Outstanding Project Awards 2024 by Forbes Marshall Pune (BTech Mechanical – 2024 Batch)